Hydraulics

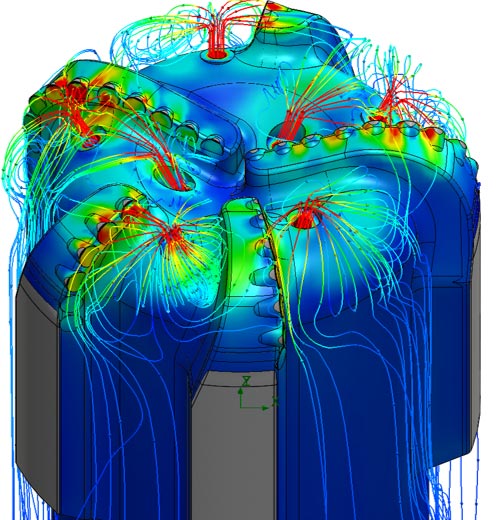

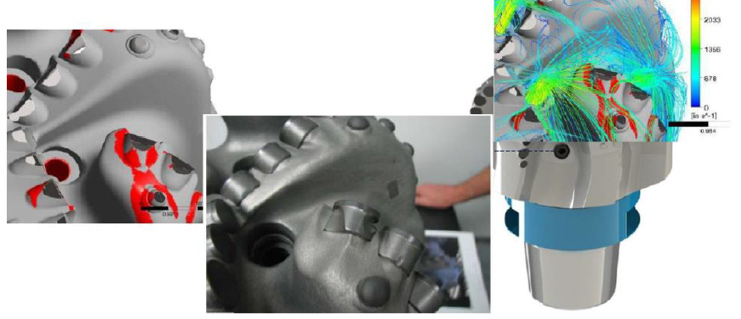

DIAMANT design engineers utilize Computational Fluid Dynamics (CFD) model to simulate the interaction of the drilling fluids with the bit and wellbore.

The CFD analysis considers variety of downhole conditions to define the optimum blade geometries and nozzle configurations for the ultimate purpose of fast evacuation of the cuttings from the bit face. This is to ensure that the bit cutting structure is always in contact with the uncut formation to improve the bit performance.

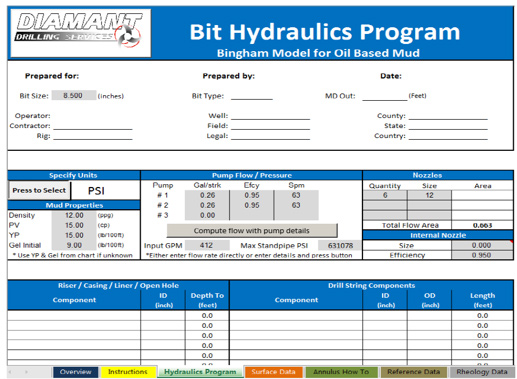

When the products are delivered to the field, the final stage of the bit hydraulics design is to decide the total flow area (TFA) for the bits. DIAMANT application engineers recommend TFAs for its products at the field level in close communication with our clients by considering the specific objectives of bit runs, BHA types and well geometries.